Denim Repair: Mending Rips, Holes, Wears & Tears in Your Jeans

There are a bunch of tutorials out there, but most of them don't aim to repair jeans to their original glory; instead, the jeans are patched or the stitching is very obvious. My goal was to create the smallest repair 'scar' possible. This is achieved professionally by Denim Therapy (send or bring to their NY office) or Denim Doctor (LA), but I wanted to see if I could do it at home with a simple, free-arm sewing machine (I love my 1916 Singer Model 15, but I can't imagine how one could get into the pant leg with a flat bed).

This week is my first experience repairing jeans, creating a photo tutorial, AND blogging. Please leave comments, suggestions, questions.

Enjoy!

Supplies -

Iron

Scissors

Interfacing

Pressing Cloth

Tissue Paper

Thread

Free-Arm Sewing Machine with Feed Dog Drop/Embroidery Foot

Pen/Disappearing Ink (optional)

Fabric Glue (optional)

Pins (optional)

Notes on Supplies -

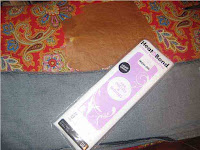

Interfacing - I use lightweight interfacing because that's what I have in my apartment. If you're purchasing interfacing purposefully for this project, I recommend a heavier weight suitable for your denim (suggestions on packaging). Or, you could probably use any kind of fusible patch. I prefer the interfacing because it's so lightweight it won't be felt by the wearer.

Pressing Cloth - any light fabric (muslin, t-shirt, tissue paper) to cover the interfacing while ironing it

Tissue Paper - when you iron on the interfacing, put tissue paper inside the leg so that none of the adhesive sticks to the other side of the jeans.

Thread - Color matching and quality is key. I only use Gutermann, at the advice of so many sewers. To color match, bring the jeans with you to a sewing store. Unravel the spool and place the thread along your jeans. You may require two or three thread colors. There are only so many shades of blue available, so just do the best you can. Slightly darker is better than lighter. Also, I use polyester thread, which has a sheen. If you want to perfect the look, you might try all cotton thread instead.

Sewing Machine - Because a pant leg can be narrow, you will most likely need a free-arm sewing machine. In addition, you will need a feed dog drop function and/or a darning/embroidery foot - either is sufficient, both is ideal. With the feed dogs down, you can move your jeans left and right, not just front to back. An embroidery foot gives you more freedom to move the fabric.

Fabric Glue - I find this very helpful to secure the jean fray along its original grainline, which looks better than if the fibers were going in all different directions. Use sparingly and wait for a test patch to dry to see if the glue causes any fabric discoloration.

Pins - I use them to position and hold the jean frays where I want them.

Process -

Step 1: Interfacing

Drop the feed dogs. Set your stitch length to .2m or whatever the smallest setting is on your machine.

Load the appropriate color thread. You want the bobbin thread to be lighter blue color, but if you want to be perfect, change it with every upper thread color change; in case the thread tension is wrong, you won't be able to notice. This is not the kind of project for a seam ripper. (Note: I originally had white bobbin thread, and you can see some of the stitches due to bad thread tension. Halfway, I changed my bobbin thread and tried to go over the white spots to cover it up.)

Start slow. Take the smallest stitches possible. Go up and down the hole as straight as possible, matching the grainline. Make sure to stitch beyond the hole for stability and reinforcement. Stitching further beyond the hole might even help camouflage it better. I haven't repaired enough jeans to figure this out yet.

I turned my sewing machine at a 45-degree angle since that was most comfortable for me. You can stop frequently and adjust to find your best position.

Repeat the stitching with different thread colors as much as necessary until you achieve a satisfactorily result.

*If the tear is near a seam, like the crotch for example, you may have to undo the seam, repair the hole, and re-stitch the seam.

Step 4: Finishing

Take the jeans off the sewing machine, trim the threads, iron/press stitches on right and wrong sides of jeans.

This week is my first experience repairing jeans, creating a photo tutorial, AND blogging. Please leave comments, suggestions, questions.

Enjoy!

Supplies -

Iron

Scissors

Interfacing

Pressing Cloth

Tissue Paper

Thread

Free-Arm Sewing Machine with Feed Dog Drop/Embroidery Foot

Pen/Disappearing Ink (optional)

Fabric Glue (optional)

Pins (optional)

Notes on Supplies -

Interfacing - I use lightweight interfacing because that's what I have in my apartment. If you're purchasing interfacing purposefully for this project, I recommend a heavier weight suitable for your denim (suggestions on packaging). Or, you could probably use any kind of fusible patch. I prefer the interfacing because it's so lightweight it won't be felt by the wearer.

Pressing Cloth - any light fabric (muslin, t-shirt, tissue paper) to cover the interfacing while ironing it

Tissue Paper - when you iron on the interfacing, put tissue paper inside the leg so that none of the adhesive sticks to the other side of the jeans.

Thread - Color matching and quality is key. I only use Gutermann, at the advice of so many sewers. To color match, bring the jeans with you to a sewing store. Unravel the spool and place the thread along your jeans. You may require two or three thread colors. There are only so many shades of blue available, so just do the best you can. Slightly darker is better than lighter. Also, I use polyester thread, which has a sheen. If you want to perfect the look, you might try all cotton thread instead.

Sewing Machine - Because a pant leg can be narrow, you will most likely need a free-arm sewing machine. In addition, you will need a feed dog drop function and/or a darning/embroidery foot - either is sufficient, both is ideal. With the feed dogs down, you can move your jeans left and right, not just front to back. An embroidery foot gives you more freedom to move the fabric.

Fabric Glue - I find this very helpful to secure the jean fray along its original grainline, which looks better than if the fibers were going in all different directions. Use sparingly and wait for a test patch to dry to see if the glue causes any fabric discoloration.

Pins - I use them to position and hold the jean frays where I want them.

Process -

Step 1: Interfacing

With the interfacing over the patch, use a disappearing ink pen to outline the area that needs repair. Make it at least 1/2" to 1" larger on all sides so the interfacing has something to fuse onto (you'll see below that I had to do it twice because the interfacing was too small the first time). Cut interfacing with scissors.

Follow package instructions, e.g. iron interfacing with press cloth for 10-15 seconds, with tissue paper inside the leg. Check adhesion and repeat if necessary.

*Showing the repeat interfacing. Though the horizontal fibers are interfaced, the interfacing came off the top of the jeans. I cut another piece of interfacing and ironed it, overlapping with the original piece.

Step 2: Gluing

Gluing gives me more control of the final look because I can place the torn fibers exactly how I want them to lay. Use very small amounts of glue, spread thin (with a pin), and place the fibers on the hole, in their original position and direction (again, with a pin. I used a different one than the glueing pin so the jeans don't have unecessary glue anywhere).

Step 3: Stitching

This is where the fun (read: challenge) begins. Figure out how you can best access the hole. For me, this means sticking the bottom of the sewing machine into the leg of the jean, and scrunching the jean leg as much as possible. This is no easy task if you're dealing with small-waisted or skinny/straight-leg jeans.

Drop the feed dogs. Set your stitch length to .2m or whatever the smallest setting is on your machine.

Load the appropriate color thread. You want the bobbin thread to be lighter blue color, but if you want to be perfect, change it with every upper thread color change; in case the thread tension is wrong, you won't be able to notice. This is not the kind of project for a seam ripper. (Note: I originally had white bobbin thread, and you can see some of the stitches due to bad thread tension. Halfway, I changed my bobbin thread and tried to go over the white spots to cover it up.)

Start slow. Take the smallest stitches possible. Go up and down the hole as straight as possible, matching the grainline. Make sure to stitch beyond the hole for stability and reinforcement. Stitching further beyond the hole might even help camouflage it better. I haven't repaired enough jeans to figure this out yet.

I turned my sewing machine at a 45-degree angle since that was most comfortable for me. You can stop frequently and adjust to find your best position.

Repeat the stitching with different thread colors as much as necessary until you achieve a satisfactorily result.

*If the tear is near a seam, like the crotch for example, you may have to undo the seam, repair the hole, and re-stitch the seam.

Step 4: Finishing

Take the jeans off the sewing machine, trim the threads, iron/press stitches on right and wrong sides of jeans.

Tah-Dah!

More repairs:

those are my jeans! they look awesome! i am SO excited!

ReplyDeleteVery Good Thanks for all the tips.

ReplyDeletegreat tips

ReplyDeleteI can't wait to try this! My fave jeans just got a big knee rip. Thanks for posting.

ReplyDeleteThank you for the helpful tips, I ripped my jeans a few weeks ago and have been looking for help to repair them so thanks!

ReplyDeleteIt is best to wash your jeans in tepid water so as to maintain the quality of the jeans' fabric. If eans that are not too soiled they should be soaked in lukewarm water and soap for 10-15 minutes before rinsing - no washing machine.

ReplyDeletethanks for the tip!

DeleteHi I work at The Buckle and I repair denim every day, a free service to our valued guests. I do pretty much the same thing only if you open the outside seam (not the double topsitched inner seam) you have easier access to the tear and much more room to manipulate your work! Then re-sew that seam! Also we have found that for almost all shades of denim, except the very lightest we use two shades of gray thread. A silvery gray and a charcoal gray. Great tutorial!

ReplyDeletethank you for the tip and the encouragement!

Delete